Shipping

1 - 2 Days

Heavy Duty Poly Tarp - Flame Resistant - Full 20 Mil

• Stop replacing cheaper FR poly tarps

• Rugged 10 oz. sq yd, 3 ply, 2500 denier fabric

• Meets CPAI-84 & NFPA 701 fire standards

• Heat-welded seams & hems

• High UV Resistance & Minus 40 °F cold crack

Made In The USA

By choosing this product, you're supporting American craftsmanship, local jobs, and ethical manufacturing. Built with care — designed to last.

Shipping

1 - 2 Days

The Best Strength to Weight Ratio

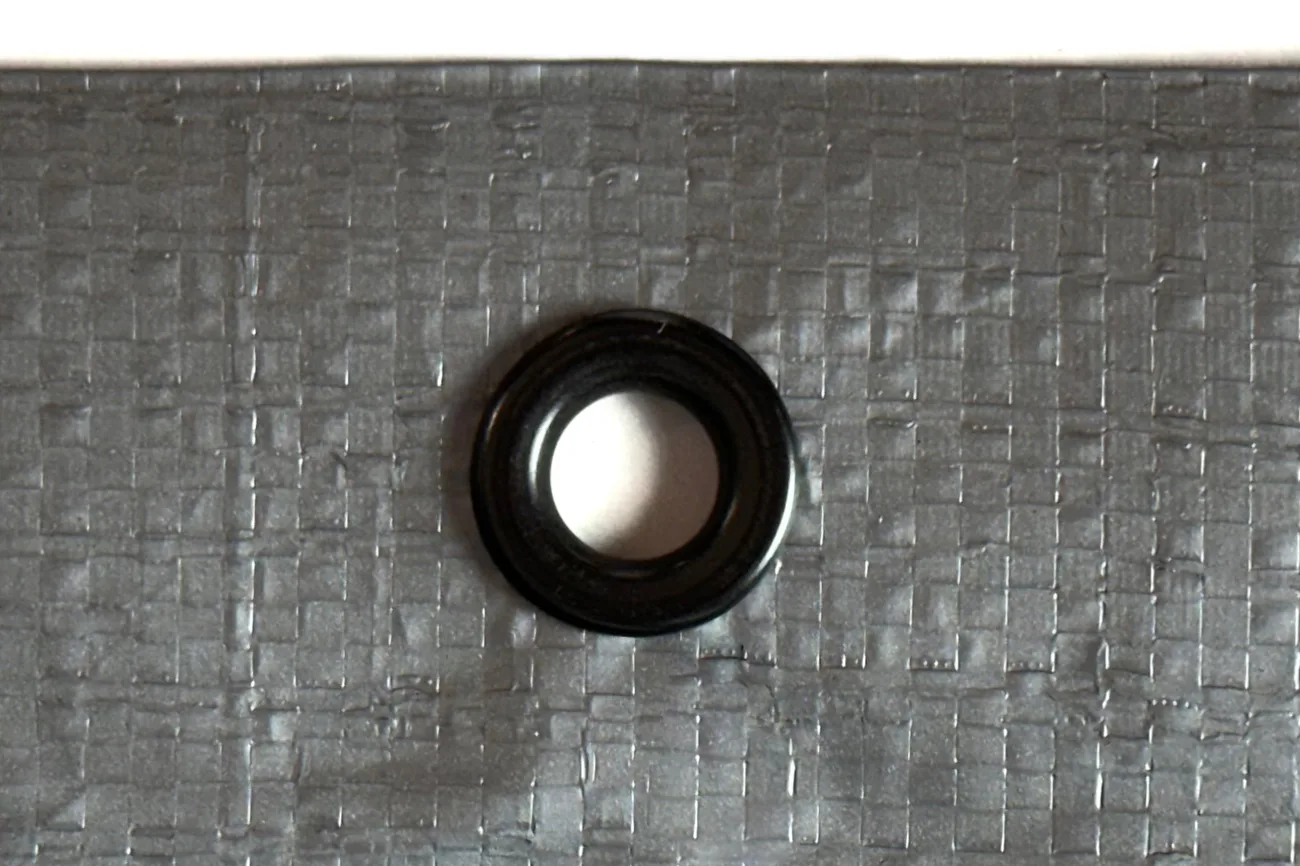

Made from rugged 20 mil (10 oz. sq. yd.), 3 ply, 2500 denier reinforced polyethylene fabric with "FR" printed every yard, this tarp is much lighter than traditional vinyl or canvas options, but does not sacrifice toughness or performance. Our tarps are made with heat-welded hems and seams that are both more durable and more waterproof than traditional sewing. The reinforced poly coating and 3 ply fabric is incredibly robust and resistant to abrasion and tearing.

This heavy duty tarp is an excellent option to have on hand for unexpected needs. The combination of light weight and performance makes it easy to store and to deploy in a hurry.

Real Heavy Duty Flame Retardant Polyethylene

The polyethylene fabric used to make this tarp is clearly marked with an FR every yard. It is formulated to slow the spread of flames and resist sparks, meeting CPAI-84 and NFPA 701 fire safety standards, making it an effective tool for establishing a safe working environment. It is ideal for:

• Covering flammable materials

• Creating temporary enclosures in high-risk areas

• Enclosing construction sites and scaffolding

• Isolating welding and fabrication work

• Protecting combustable cargo in transit

Advertising Poly Tarps in the Sixties

One of our favorite ways to show the strength of our product is the pull test pictured to the right. We take a small sample of our fabric, cut a slit in the middle, and let people try to tear it. It doesn’t work; even with a slit, the fabric won’t tear further just by pulling. It’s easy to see why this has been an effective way to sell our tarps for decades!