Tarp Buying Guide: Materials, Thickness & Applications

Complete guide to choosing tarps: poly tarps, vinyl tarps, canvas tarps & mesh tarps. Compare tarp materials, thickness ...

Cart is Empty

Product Guide

In industries where hazardous materials and processes are commonplace, fire safety is not just a regulatory requirement but a critical component of operational integrity. Implementing robust fire safety measures protects employees, assets, and the environment. This guide outlines best practices for fire safety in hazardous workplaces, aligning with OSHA standards and NFPA 70E guidelines, and explores tools like flame-resistant tarps that mitigate risk.

Hazardous industries often involve flammable materials, high-temperature processes, and complex machinery, all of which elevate fire risks. Common fire hazards include:

Understanding these risks is the first step in developing effective fire prevention strategies.

The Occupational Safety and Health Administration (OSHA) provides comprehensive guidelines to mitigate fire hazards in the workplace. Key measures include:

A prevention plan identifies potential fire hazards and outlines procedures to prevent fires. It should include:

A list of major fire hazards and proper handling/storage procedures

Maintenance of safeguards on heat-producing equipment

An emergency action plan details the actions employees must take in the event of a fire, including:

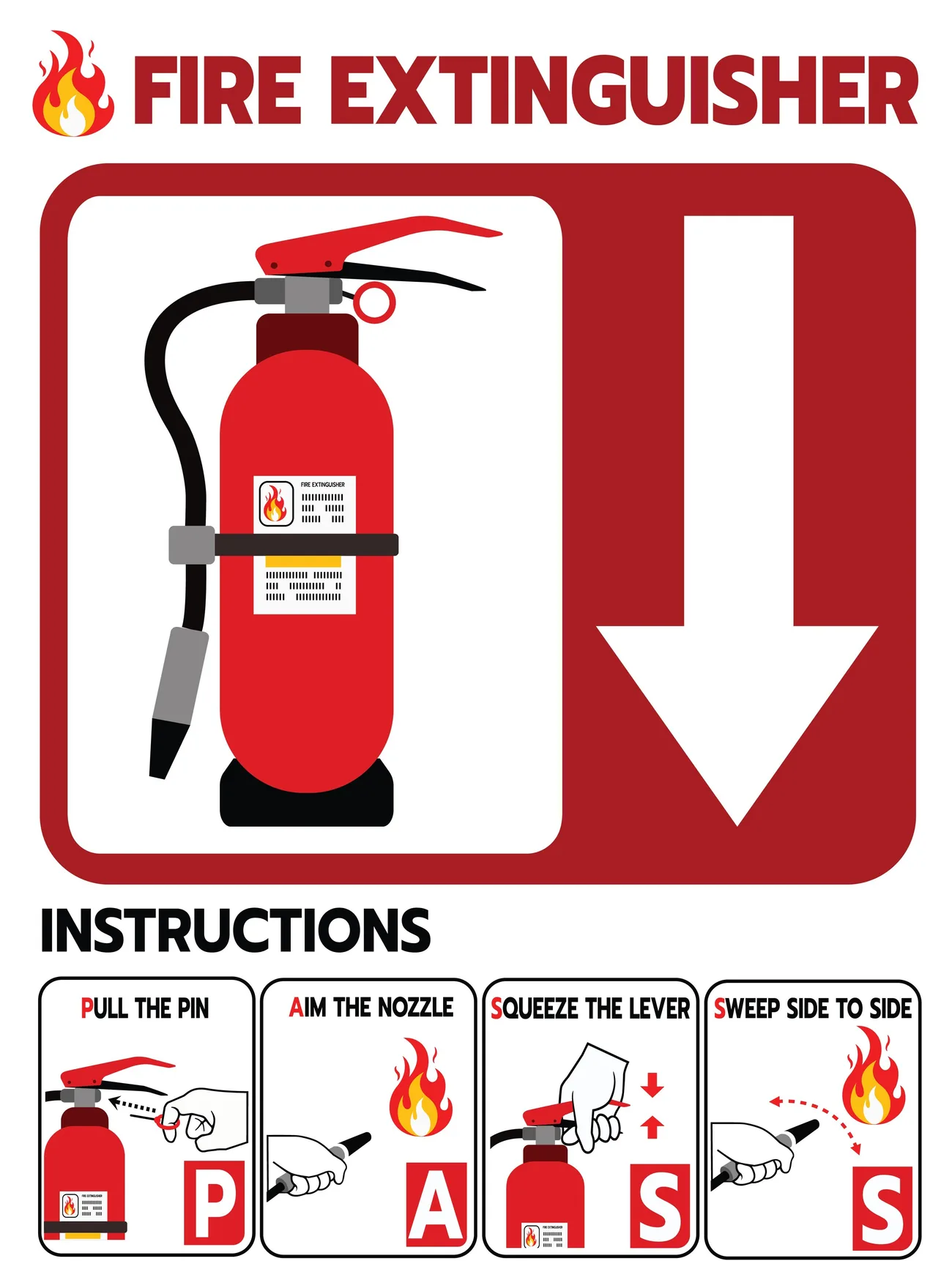

Employees must be trained on the proper use of fire extinguishers. Training should cover:

Types of fire extinguishers and their appropriate use

PASS technique (Pull, Aim, Squeeze, Sweep)

Limitations and risks associated with fire extinguisher use

Regular drills and refresher courses ensure preparedness and compliance with OSHA standards.

Looking for Flame-Resistant Tarps? Check out Humphry's tarp collection.

Electrical hazards are a significant concern in hazardous industries. The National Fire Protection Association's (NFPA) 70E standard provides guidelines to protect workers from electrical hazards, including:

Arc Flash Risk Assessment: Identifying potential arc flash hazards and implementing protective measures

Establishing Electrically Safe Work Conditions: De-energizing equipment before maintenance

Personal Protective Equipment (PPE): Using appropriate PPE for electrical work

Training and Awareness: Educating employees on electrical hazards and safe work practices

Compliance with NFPA 70E not only enhances safety but also aligns with OSHA requirements for electrical safety in the workplace.

Regular fire risk assessments are crucial for identifying and mitigating potential fire hazards. Assessments should:

Evaluate fire hazards associated with processes, equipment, and materials

Assess the effectiveness of existing prevention measures

Recommend improvements or additional controls

Be documented and reviewed periodically, especially after changes in operations

Engaging qualified professionals to conduct these assessments ensures a thorough evaluation and compliance with safety standards.

Effective fire prevention in hazardous industries involves a combination of engineering controls, administrative policies, and employee training:

Fire Detection & Suppression Systems: Install smoke detectors, fire alarms, and sprinkler systems

Ventilation Systems: Prevent the buildup of flammable vapors

Explosion-Proof Equipment: Use equipment designed to prevent ignition in hazardous environments

Flame-Resistant Tarps: Protect exposed flammable materials & leverage the science behind fire-retardant tarps

Safe Work Procedures: Develop & enforce procedures for handling flammable materials and performing hot work

Housekeeping Practices: Maintain cleanliness to prevent the accumulation of combustible materials

Storage Protocols: Store flammable substances in appropriate containers and designated areas

Fire Safety Training: Educate employees on fire hazards, prevention measures, and emergency response

Drills and Simulations: Conduct regular fire drills to reinforce training and evaluate response effectiveness

Continuous Education: Provide ongoing training to keep employees informed about hazards & safety procedures

A fire safety checklist serves as a practical tool to ensure all safety measures are in place and functioning correctly. Key elements to include:

Fire Extinguisher Accessibility: Ensure extinguishers are readily available and inspected regularly

Emergency Exits: Verify that exits are marked, unobstructed, and functional

Alarm Systems: Test fire alarms and detection systems periodically

Storage Compliance: Verify flammable materials are stored correctly, using fire-resistant tarp coverings

Electrical Safety: Inspect wiring and equipment for signs of wear or damage

Employee Training Records: Maintain documentation of fire safety training sessions

Looking for Flame-Resistant Tarps? Here is our flame resistant collection.

Common hazards include flammable liquids and gases, faulty electrical equipment, hot work operations, and combustible dust accumulation.

Implement a layered approach: identify ignition sources, separate them from combustibles, enforce rigorous housekeeping, and install automatic detection/suppression systems. Pair these measures with a written Fire Prevention Plan (FPP) that is reviewed at least annually and whenever processes change.

Certified flame-resistant tarps (NFPA 701, CPAI-84, or California Title 19) block sparks, slag, and radiant heat, preventing ignition of nearby materials and containing hot debris within a controlled area—an inexpensive engineering control that supports OSHA 1910.252 requirements.

NFPA 70E focuses on electrical and arc flash safety, but using protective barriers like flame-resistant tarps can be a best-practice supplement during arc-flash risk mitigation.

Get a Free Quote

Ready to order or looking for more info? We’re here to help!Questions?

Call Us Today!

Visit Us

Pennsylvania:

5000 Paschall Ave

Philadelphia, PA 19134

Indiana:

11 Lousisa St.

Gosport, IN 47433